Auto body collision repair involves critical system calibration for both safety and quality. This goes beyond fixing dents, requiring precise adjustments to meet original manufacturer specs. Key systems like Anti-lock Braking Systems (ABS), Electronic Stability Control (ESC), airbags, and frame straightening demand meticulous calibration. Regular maintenance and tool calibration, along with trained technicians following standard operating procedures, are essential practices to ensure accurate and safe repairs.

In the realm of auto body collision repair, precision is paramount to ensure safe and effective restoration. Safety systems calibration plays a crucial role in this process, aligning vehicles’ critical components with manufacturer specifications. This article delves into the significance of calibration in auto body collision repair, exploring key safety systems, their specific calibration processes, and best practices for achieving accurate results. Understanding these protocols is essential to maintaining both vehicle integrity and driver safety.

- Understanding the Importance of Calibration in Auto Body Collision Repair

- Key Safety Systems and Their Calibration Processes

- Best Practices for Ensuring Accurate Calibration During Repair Procedures

Understanding the Importance of Calibration in Auto Body Collision Repair

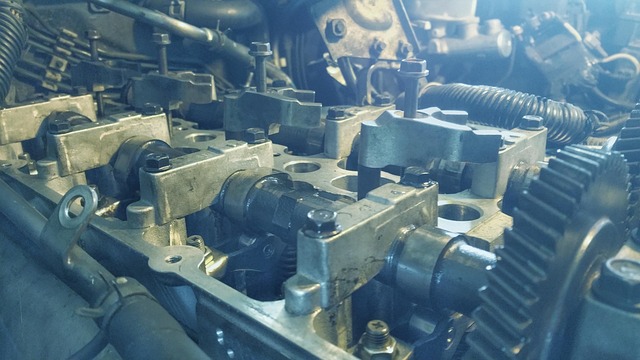

In the intricate world of auto body collision repair, calibration stands as a cornerstone of precision and safety. It’s not merely about fixing dents; it’s about ensuring vehicles return to their pre-accident condition while upholding stringent safety standards. Calibration involves meticulously adjusting various systems, from frame alignment to paint consistency, to match the original manufacturer specifications. This meticulous process is vital in mitigating risks associated with subpar repairs, guaranteeing structural integrity, and preserving the vehicle’s overall performance and safety features—a critical aspect for all auto body collision repair services, encompassing even high-end makes like Mercedes Benz repair.

Moreover, calibration plays a pivotal role in achieving seamless vehicle paint repair and flawless auto bodywork. Inaccurate calibrations can lead to inconsistencies in paint finishes, gaps in panel fitting, or misaligned components. These issues not only compromise the aesthetic appeal but also affect the structural soundness of the vehicle. Therefore, regular calibration becomes indispensable for any reputable collision repair shop, ensuring that every restored vehicle meets the highest standards of quality and safety across all repairs, be it a simple dent removal or complex vehicle paint repair jobs.

Key Safety Systems and Their Calibration Processes

In the realm of auto body collision repair, several key safety systems require meticulous calibration to ensure optimal performance and driver protection. Among these, Anti-lock Braking Systems (ABS) stand out for their crucial role in preventing wheel lockup during hard braking events. Calibration involves testing and adjusting the system’s responsiveness, ensuring it activates smoothly and efficiently under various conditions. Similarly, Electronic Stability Control (ESC) systems, which help drivers maintain control in skidding or loose conditions, demand precise calibration to accurately detect and correct vehicle instability.

Other vital safety systems include Airbag Timing and Sensor Calibration, where the timing and deployment of airbags during a collision are fine-tuned for maximum effectiveness. Frame straightening, an essential auto body service, is also tied to safety system calibration, as it ensures structural integrity post-repair. Proper auto maintenance practices, such as regular checks and updates, contribute to keeping these systems calibrated and ready to respond effectively in the event of a collision.

Best Practices for Ensuring Accurate Calibration During Repair Procedures

To ensure accurate calibration during auto body collision repair procedures, several best practices should be rigorously followed. First, all calibration tools and equipment must be regularly maintained and calibrated according to the manufacturer’s specifications. Using well-maintained tools ensures precise measurements, which are critical for consistent and safe repairs.

Secondly, technicians performing frame straightening or car body repair should have comprehensive training in calibration techniques. This includes understanding how various systems interact and knowing when to adjust settings to achieve optimal results. Regular staff training sessions and ongoing education can help maintain a high level of proficiency, minimizing errors that could compromise safety. Additionally, establishing standard operating procedures (SOPs) for each step of the repair process, especially those involving complex calibration, helps ensure consistency and reduces the risk of human error.

In the realm of auto body collision repair, accurate safety systems calibration is paramount. By understanding the critical role it plays in ensuring vehicle and driver safety, adopting best practices for calibration, and familiarizing ourselves with key systems’ unique processes, we can deliver high-quality repairs that meet modern safety standards. This meticulous approach to calibration is not just a best practice—it’s a step towards revolutionizing the industry, fostering safer vehicles, and tranquilizing drivers on the road.